Where ‘smart traffic’ has already 417 billion hits on google, I only found ‘smart air’ for a kind of door lock and ‘smart drone’ for an advanced toy drone. But definitely, drones are so hot that they will become part of something called ‘smart air’. The SESAR project predicts that drones will make 250 billion hours of flight in the European Union alone. For comparison: this is far more than the air traffic of ‘normal’ airplanes today.

Because drones are using many sensors, we did some research how the use of drones can grow to maturity and fuel ‘smart air’. Today we talk about challenges for delivery drones.

Delivery drones

No wonder, drones have proven to be very convenient already and have even more promises in store. Soon, it will be commonplace that drones are delivering packages, from hot pizzas to even more urgent medicines. And even humans: the first drone taxis are already being tested. At this moment, drones are already used for drag-and-drop deliveries in some rural and faraway areas. Most articles on the internet talk about the use in drones in big city areas. And there they have the big advantage of an -still- almost empty sky instead of congested roads and overfull parking places. For that, delivery by drones will be faster and more predictable.

But until use of drones are entirely tried and tested, most drone developments will take place on rural environments. Because here the risk of large damage is a lot smaller when something will go wrong. In time, delivery drones will still be used in rural places. Maybe as a standalone, maybe in combination with self-driving trucks. Reach will not be a big problem, since the whole word is getting connected fast. So, reach will almost only depend on battery endurance. And for now, these batteries have only a limited capacity for distance and cargo.

Challenges while travelling

Like all delivery services, drone delivery has to a pick-up a package, travel to the destination and drop-of the package. While travelling, drones have to know how to reach their destination. Meanwhile, there are some challenges:

- Risk of colliding, with other drones, birds and other air users. Just like other traffic

- And at point in time, some traffic rules have to be set in place. Sensors can help to let the drone follow these rules

- How drones can stay on course, even with wind

- Preventing drones to cross over forbidden (known) areas and unexpected ‘wrong’ areas (e.g. a building or a wood on fire)

- How to prevent a package from falling? How to alert that a package will probably fall? Or maybe the drone itself? If so, measurement can be taken. Already, there are experiments with self-destruction. But maybe more practical solutions can be found to let the drone aim for a ‘safe area’, such as a park, river, etc. for an ‘emergency landing’

- Acceptance of drones beside safety: how to guarentee privacy when drones are flying over peopled areas? Then there is the issue of noise: research shows that people find the noise of drones one of the most annoying forms of noise

Challenges with dropping the cargo

For now, the drop-of is literally done by dropping-of the cargo. Maybe with the aid of a cord which places the package as soft as possible to the ground. But anyhow: the drone stays in the air. So, technology has to get safe: for the package to be delivered undamaged. How does the drone know that the right person gets the package? And we have to prevent dogs from biting the package. And of course, to prevent that the dropped cargo will harm humans, animals or buildings or even worse.

The use of sensors

The application possibilities of drones are very promising for delivery uses. It is still in its experimental phase. But with developments going fast, soon it will reach the maturity phase. For this, there are two-fold kind of challenges.

Some are challenges on privacy, safety and security. These challenges have to be solved before the use of drones will get widespread trust and acceptance. The other are technical and communication issues: where multiple drones are being used – especially in cities- challenges how drones can and have to behave in traffic has to be solved.

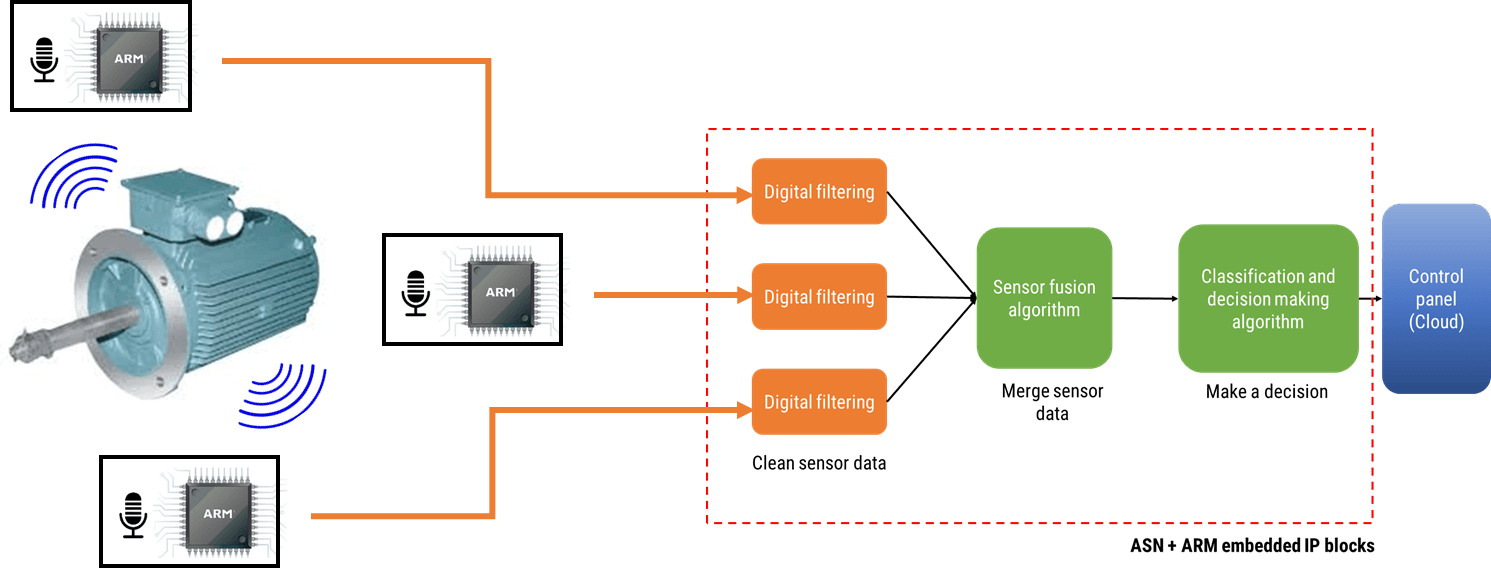

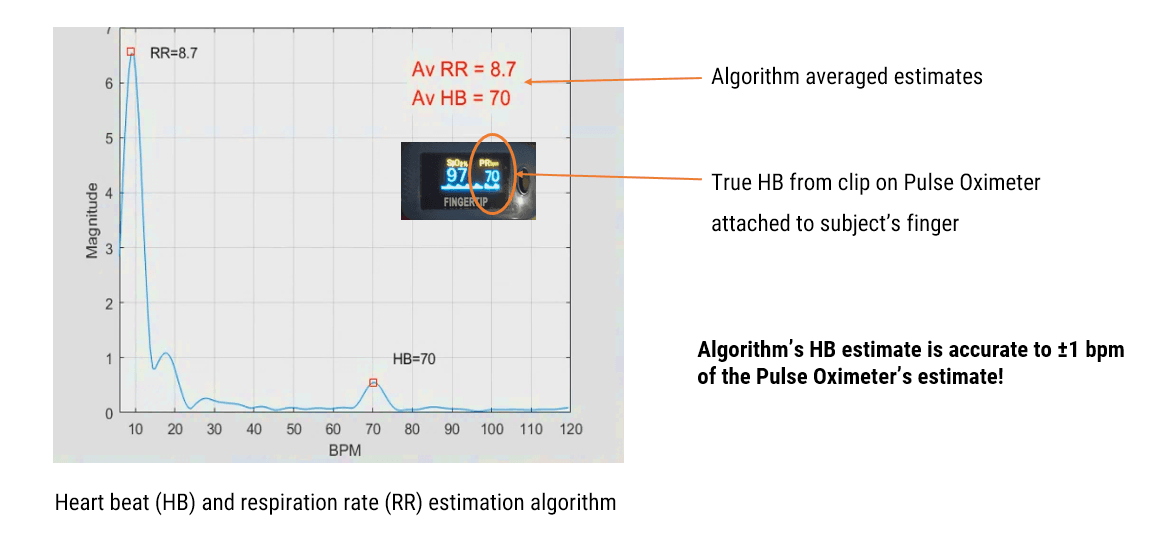

In both challenges, sensors play a pivotal role in solving the technical questions. In all cases, ASN Filter Designer can help with sensor measurement with real-time feedback and the powerful signal analyzer. How? Look at ASN Filter Designer or mail ASN consultancy: designs@advsolned.com

Do you agree with this list? Do you have other suggestions? Please let us know!