AIoT has many benefits. Those benefits can be summarized as: to save, to control, tot optimize and to innovate. How does AIOT gives you control over your processes? Some examples:

- To measure is to know

- Preventive Maintenance

- Prevent Costs and nuisance in the event of a breakdown or bad functioning

- Take the right decisions at the right time

- Track & Trace

To measure is to know

First, ‘to measure is to know’. You can only be in control of your processes, when you know how they are doing. Therefore, you need to measure.

However, AIOT is booming, still, many companies are in the blind how their processes are functioning. Or insights are only piecemeal, insight in a machine here, a process there. Which means a company isn’t in control of their whole process.

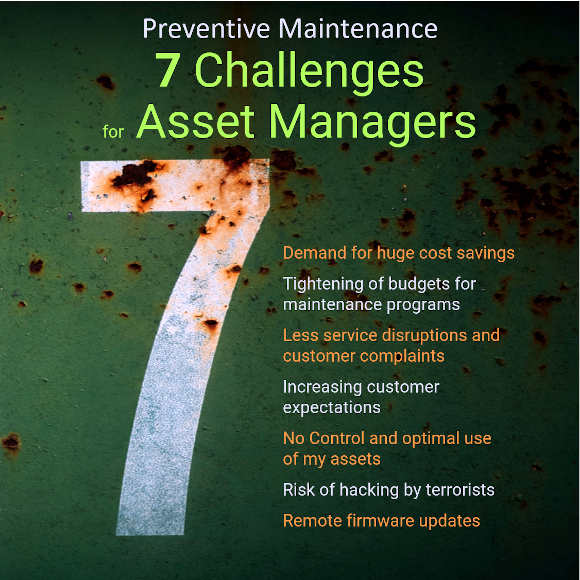

Preventive Maintenance

Know the extent to which your machines are wearing out. Prevent them from breaking down and schedule maintenance at the least bad time. In doing so, your employees can pay attention to the parts that need their attention the most: sensors keep an eye on the ‘normally’ running parts.

Prevent Costs and nuisance in the event of a breakdown or bad functioning

In many cases, a machine is a part of chain of a whole production process. Thus, a breakdown of one machine means downtime for your whole process.

With IoT, you can create new ways and do more with the same budget. Many industries are working in heavy circumstances because of dust, wind, heat, pressure, etcetera. So, it’s important to recognize if the equipment is still working properly. With IoT, you can predict and prevent equipment failure by monitoring product wear and replacement rates. As such, you improve the reliability of your assets and reduce downtime. And if you recognize little faults, you can solve them easily before they have become big and expensive problems.

Take the right decisions at the right time

Having control means that you can take the right decision at the right time. E.g.:

- To replace a motor of a machine

- Adjust the circumstances, e.g., the indoor quality in your office, the temperature in your cooling

- For both doctor and patient: Is the healing process going well? Give the proper attention to patients who needs it. Instead of giving attention to every patient, without enough time. And even better: You can optimize the healing process

- Does the patient follow the medical instructions? Examples: is he doing his therapy on time and in the right way. Does he take his medications? Especially groups of risk can be monitored so that timely action can be taken if necessary

Track & Trace

- Keep grip on the presence of all your assets at all times

- Keep grip on the production process, by knowing at any moment where parts are in the phase of a production process

- Know where employees and visitors are on your premises, e.g., to avoid them entering hazardous areas. Or to warn them in case of calamities. And avoid unwanted visitors enter your premises

Optimal circumstances

- Create optimal conditions for your employees. For example in the office by regulating a good indoor climate, which fortunately is getting more and more attention. Poor air quality can worsen the well-being of employees and visitors. It can also lead to lower productivity, for example because people feel lazy when the temperature is too high.

- Some products and services are highly dependent on maintaining optimum conditions, such as cooling, for example, perishable products. When these conditions are no longer met, all products in a batch may have to be destroyed. Through IoT you can monitor whether these optimal conditions still apply. This allows you to intervene immediately when these conditions deteriorate.